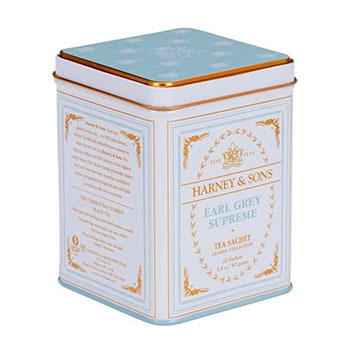

Since there is only one Earth, companies must do their best to produce products that minimize damage to the environment. When choosing the type of packaging for our products, we prefer pthat is not harmful to the environment. Therefore, we use food grade tin cans to package our products.

Recycling is an important aspect for packaging producers to consider. Studies have shown that consumers are more willing to recycle tins than plastics. In fact consumers recycle nearly 80% of tin packaging while only 30% of plastic is recycled.

How much recyclable material is used in the production of plastic and tin products?

Tinplate is a better choice. Plastic bottles and containers often contain only 3% recycled plastic material. Similar tinplate products often contain up to 25% recycled tin. This staggering difference is even more alarming when you consider that producing tinplate from recycled materials requires only 50% of the energy needed to produce it.

When using recycled metal tin cans, you can also significantly reduce the carbon footprint required to produce new tinplate products. In fact, using recycled tinplate can reduce carbon emissions by as much as 9%. Finally, it's important to note that tin can be recycled over and over again, while plastics cannot. Additionally, plastics production requires the use of petroleum, which is an extremely limited resource. It is also necessary for a variety of other industries.

While tinplate and plastics can be recycled in many cases, not every piece of tinplate and plastic can be repurposed into other products at a recycling facility. There they can be reprocessed into other products. This means that over time, landfills will become home to both materials. Plastics are notorious for taking a long time to break down.

Studies have shown that a plastic container will take up to 450 years to decompose on land. Tinplate, on the other hand, takes about 50 years. While tinplate still takes a long time to break down, it does so much faster than plastic. Plastic also ends up in the oceans, causing all sorts of problems for marine life. In fact, plastics make up 80% of marine debris. Tinplate can be recycled many times, making it a much more environmentally friendly material than plastic. Because of its recyclability, tinplate reduces the amount of waste that ends up in landfills.

In fact, the recyclability of tinplate is just one of its many benefits. For example, the use of metallic materials reduces the destruction of forests and pollution of air, water and the environment. In addition, tinplate produces fewer emissions and reduces climate change.

When determining the type of packaging for our products, we take into account the potential damage to the environment. Therefore, we are proud to package our products in custom printed tin cans whenever possible. These tin cans are 100% recyclable, making them more environmentally friendly than their plastic bottle-packaged counterparts.