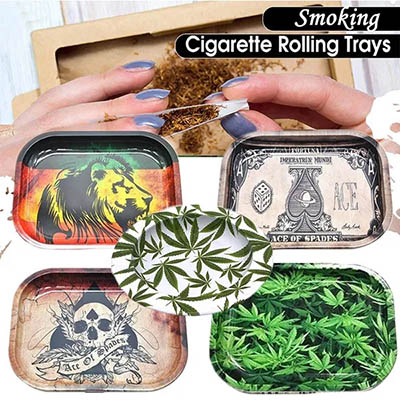

Customizing cigarette rollings trays is a fun and creative process. Here are some tips you may need when customizing your own rolling tray.

Material Selection: Make sure that the rolling tray you choose is a high-quality, durable and easy-to-clean material. High-quality tinplate is often preferred because it is less prone to rust and relatively sturdy.

Clarify design and specifications: When communicating with the manufacturer, ensure that the design and specifications are clear. Provide clear drawings of the tobacco tray design, size requirements, colors, and other details so that the manufacturer understands exactly what you expect.

Safety: Use safe materials and paints. Ensure that all paints, lacquers or varnishes used are harmless and do not release toxic substances when heated. This is especially important because smoking trays may come into contact with sources of ignition. Custom designs metal rolling trays are printed with four-color printing technology for clear graphics and high security.

Communication and design confirmation: Communicate fully with the manufacturer prior to production and make sure they are clear on your design needs. Ask for samples or design sketches to ensure your customized weed tray meet expectations.

Quality Control: Consider implementing quality control measures. You can discuss quality control processes with the metal rolling tray manufacturers to ensure that the end product meets your standards.

Communication with the manufacturer is crucial throughout the customization process. Make sure both parties have a clear understanding of the design and specifications to avoid misunderstandings and unnecessary problems. Additionally, consider building a long-term relationship with the manufacturer to make it easier to communicate and work together when other customization needs arise in the future.